-

RIMOWA’s most popular product line, the Topas.

-

RIMOWA’s electronic tag technology links a user’s suitcase to their smartphone, replacing conventional paper tags.

-

Not unlike an airplane, luggage crafted by RIMOWA is designed to fly—frequently.

-

The company has long referenced the world of aviation for its trademarked designs.

RIMOWA Luggage

In the groove.

Not unlike an airplane, luggage crafted by RIMOWA is designed to fly—frequently.

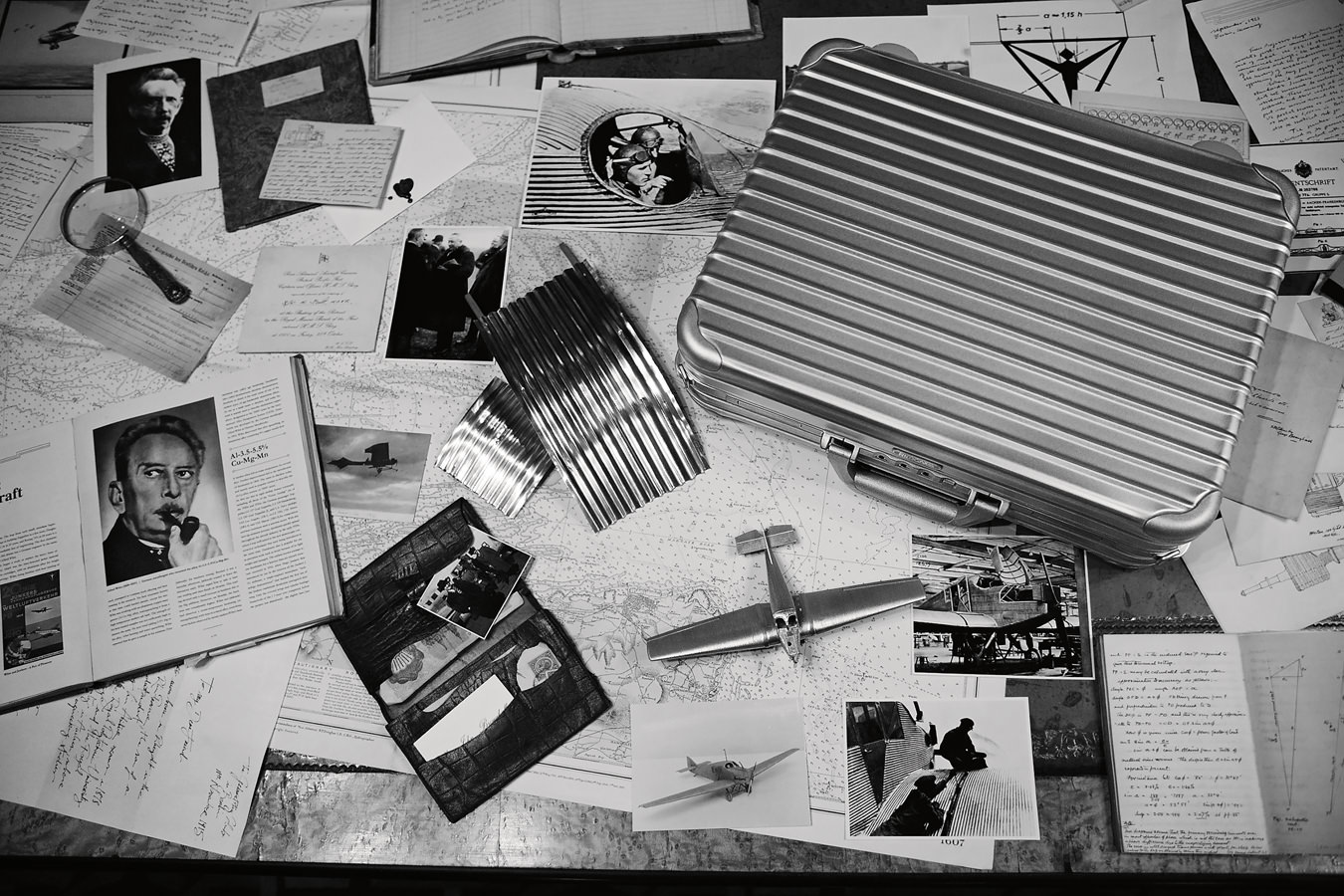

Known for its distinctively corrugated cases, the company has long referenced the world of aviation for its trademarked designs. “Junkers airplanes have always been the inspiration for RIMOWA,” affirms Dieter Morszeck, RIMOWA’s CEO for the past 44 years. Standing on the edge of the Dübendorf airfield outside Zurich, Switzerland on a clear day in early autumn, the luggage magnate has shed a suit and tie for a rust-brown leather jacket and aviator sunglasses. That’s because Morszeck, a trained pilot with 34 years of experience under his belt, isn’t presiding over a boardroom today, but the cockpit of an airplane.

On the grass runway behind him is a silver Junkers F13 airplane with RIMOWA: The Luggage with the Grooves painted across its corrugated fuselage. Part passion project, part homage to the Roaring Twenties, the plane was commissioned by Morszeck as the first airworthy F13 replica to be built within a modern context. On this day, the new vessel takes its first official flight—a 15-minute journey above the Swiss countryside—with Morszeck at the controls. Monumental flights are nothing new for the aviation enthusiast who once flew across the Atlantic in a restored Ju 52 Junkers plane, but this launch, seven years in the making, is personal.

“I was a little bit nervous,” admits Morszeck to the gathering of media and VIPs in attendance, which includes Hans-Walter Bender, who rode on the very first Junkers plane in 1929 at the age of six. “But this is one of my life highlights,” says Morszeck. “After such a long time, it is good to see the project finished.”

The original Junkers planes were the first all-metal commercial aircraft in the world. Designed by German engineer Hugo Junkers using an aluminum alloy, the planes pioneered a lightweight, low-maintenance mode of transportation that revolutionized aviation and paved the way for the carbon-composite planes we travel on today. The iconic outer shell design also inspired the silver grooves of each RIMOWA suitcase, which have come to define one of the most desirable luggage labels on the planet. Indeed, the grooves seem etched into the company’s very DNA; even RIMOWA’s Cologne, Germany headquarters are clad in a silver-ridged material.

Known for its distinctively corrugated cases, the company has long referenced the world of aviation for its trademarked designs.

Let’s rewind, for a moment, to 1898, when Paul Morszeck (Dieter’s grandfather and company founder) started making wooden suitcases for Cologne’s discerning clientele. His son, Richard, brought the first aluminum trunks to market in 1937, and the corrugated silver suitcases debuted in 1950, quickly becoming favoured by the international jet set. (The brand name RIMOWA is derived from the name of its founder: RIchard MOrszeck WArenzeichen.) When Richard’s son, Dieter, came on the scene, he developed the first waterproof lightweight metal case. The 1976 debut quickly became beloved by photography and film crews travelling with delicate equipment to extreme conditions. In 2000, Dieter coined the tag line “Handmade meets High-Tech” for the first use of polycarbonate in luggage: durable, lightweight, and modelled on aircraft construction. These days, RIMOWA suitcases are immediately recognizable as markers of quality as they roll through airports around the globe. (Their appearance is so coveted that the company has taken design copycats to court on more than one occasion—and won.)

The suitcases are made from either traditional aluminum or light polycarbonate—specifically a virgin German polycarbonate—and the brand portfolio includes six polycarbonate luggage lines and six aluminum ones, along with leather goods like wallets and cellphone cases, and a handful of unique offerings such as reinforced champagne cases and travel humidors for cigars, all shrouded in silver grooves. Behind the scenes, each suitcase takes around 210 steps to produce and is worked on by at least 19 separate sets of hands in a highly rigorous process. For the aluminum cases specifically, rivets crafted from that same metal—another Junkers innovation still used today—join the frames to the shell, giving the cases a strength of 27,000 pounds per square inch; wheels with a patented design are engineered to travel smoothly over any surface; and inside liners and dividers are all hand-applied. In a final step, a worker hits the bag with a large rubber hammer to ensure the case is properly balanced and, well, as tough as can be. (The cases are certainly sturdy. In one instance, the factory in Germany had an aluminum RIMOWA brought in after an airplane crash; the case had survived with mere scratches.)

With good reason, the company keeps certain steps of its construction process as highly guarded secrets inside each of its four global factories, which are located in Canada (Cambridge, Ontario), Germany, Brazil, and the Czech Republic. Almost 1,500 cases are made each day in the Cambridge facility alone, and business is clearly booming; company revenues for 2016 are expected to exceed 400 million euros.

High-tech, high-flying German luggage company RIMOWA has a repertoire of coveted cases and continues to innovate in the name of air travel.

This fall, RIMOWA sold a majority share of 80 per cent to the LVMH (Moët Hennessy Louis Vuitton) group, making the luggage company the first German maison of the luxury conglomerate. The sale, still subject to the approval of the competition authorities, is valued at 640 million euros and should be finalized by January 2017, whereupon 24-year-old Alexandre Arnault will be appointed co-CEO of RIMOWA.

Despite consistent growth, the company continues to innovate with its latest technological advancement, the RIMOWA electronic tag. The e-tag continues along the path of paper-free travel technology that mobile boarding passes started. With an e-ink display screen the same size as a luggage tag (and built on the principles of a Kindle), RIMOWA’s e-tag communicates data to a user’s smartphone—both iOS and Android—via Bluetooth and an app, also logging the information into an airline’s system. Users can synchronize the tag with their flight information, then simply direct-drop the bag at a dedicated airport counter. Though not equipped with a GPS per se, the case can still be tracked at each stage of its journey and, even if the electronic module’s batteries (two AAA) were to die en route, the e-ink display is designed to retain the image encripted onto it.

As far as luggage security goes, the database is monitored by the German data centre, which is subjected to the strictest laws in the world, making it the most secure smart luggage technology on the market today. Currently there are about 7,000 registered users, and soon customized possibilities will be made available, such as adding e-mail addresses or photos to the tags. Unsurprisingly, RIMOWA launched the e-tag first with fellow German company Lufthansa, and come December will add EVA Air as the first flagship Asian carrier.

“It might look like a sexy bag, but it’s actually a game changer,” explains Björn Becker, the senior director of product management for ground and digital services at Lufthansa. “Out of the [major] airports in the world, every airline needs to understand the technology.”

Sven Lepschy, vice-president of the RIMOWA electronic tag, cuts to the chase. “Make no mistake about it, this is the future. In 10 years, we simply will not have paper tags anymore.” The future is something that RIMOWA is good at anticipating—though never forgetting the past along the way.