-

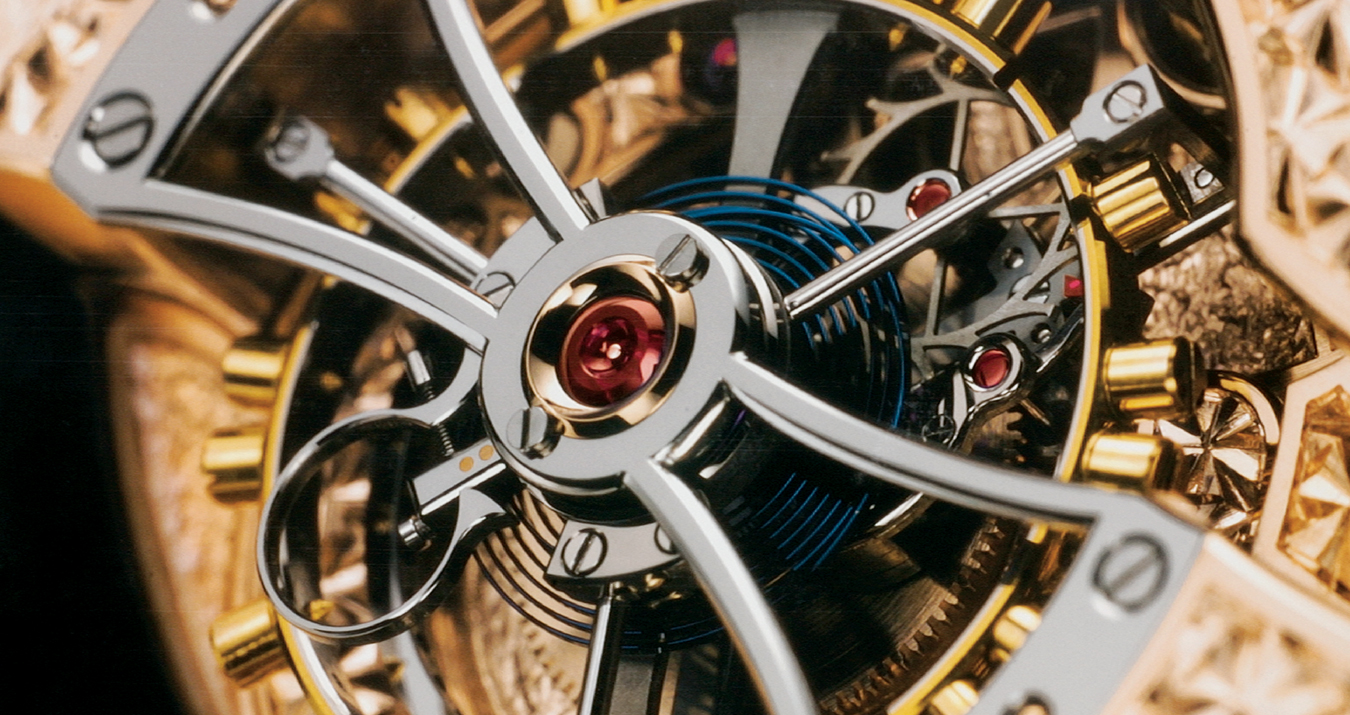

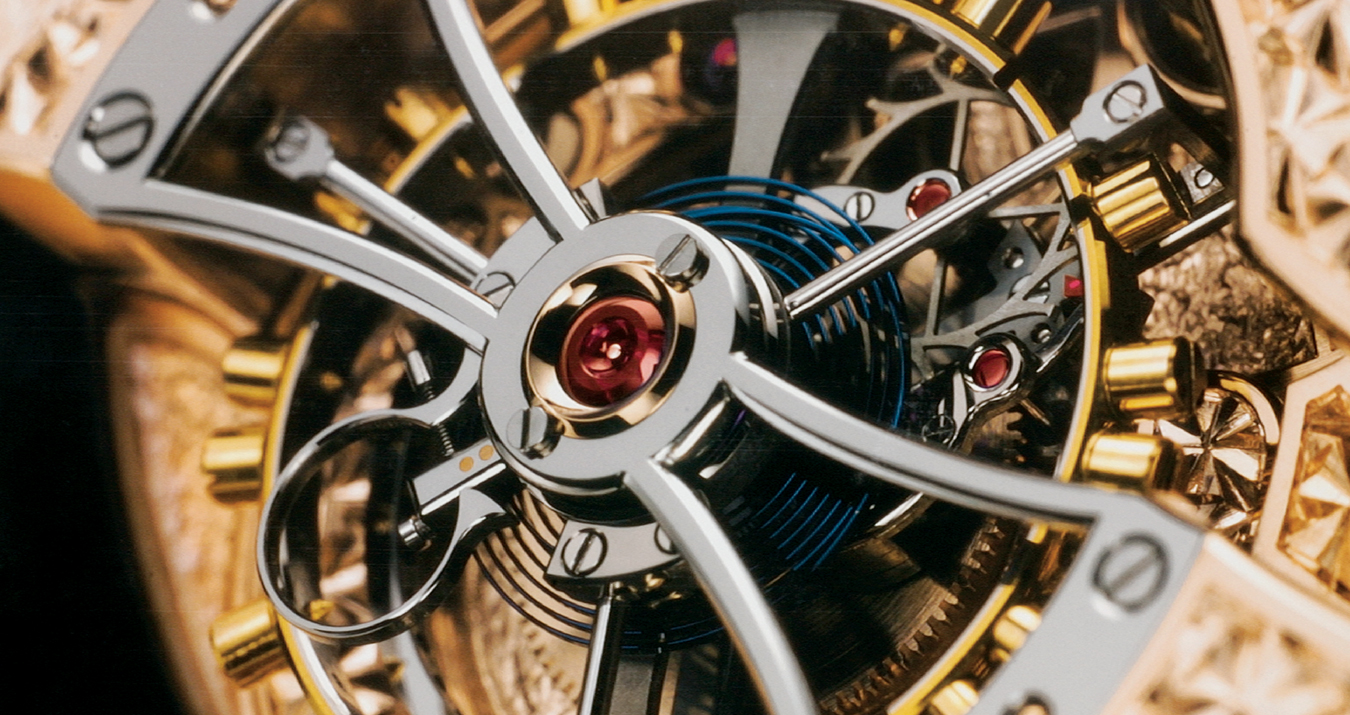

Skeleton Tourbillon Pocket Watch in Rose Gold, 1930 ($395,000).

-

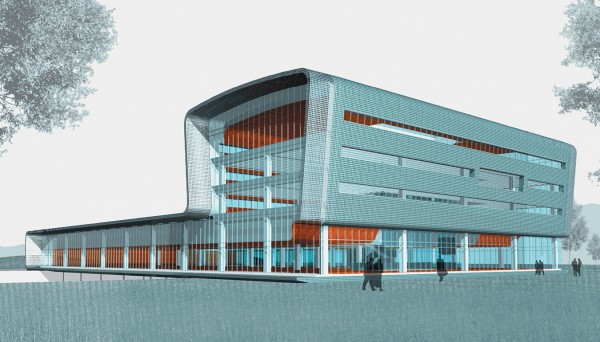

Architectural drawing of new facility, designed by B. Tschumi.

-

Egerie l.

-

Egerie 4.

-

Master Toledo.

Vacheron Constantin

The complications.

Skeleton Tourbillon Pocket Watch in Rose Gold.

Hubert Hirner has a business card that reads “Technical Trainer”. Should you ever have the pleasure of meeting him at his office and workbench in the Vacheron Constantin building in Switzerland’s Vallée de Joux, at the modern-day equivalent of a Renaissance cabinet, where watches were, and still are, made completely by hand, you would quickly realize what Hubert actually is. A watchmaker.

Cabinotiers occupied the upper levels of buildings in this valley, since natural light was most abundant there, and they spent most of their winter months at workbenches, engaged in the painstaking challenges of making intricate timepieces. Technical proficiency, manual skill, familiarity with science, and a certain open-mindedness were the prerequisites, and Jean-Marc Vacheron was one such person. He opened his own workshop in 1755. Over the next century and a half, virtually all of the industry’s decisive developments were conceived, including the novel idea of the wristwatch, introduced to the public only in 1905.

Architectural drawing of new facility, designed by B. Tschumi.

Francois Constantin joined the company in 1819 at the request of Jacques-Barthelemy Vacheron, adding ambition, enterprise and natural sales skills to the firm. Technical quality and the greatest possible refinements in decoration and finishing were his goals, and as the firm’s watchmakers adopted his passion, the company’s reputation began to spread, across Europe and to America. By 1821, demand far exceeded supply, and Vacheron acknowledged the necessity of partial automation, while strictly maintaining quality.

Enter Georges-Auguste Leschot, engineer and technical director of the firm. He developed machines, one of which is still on display and in working order at the company’s museum in Geneva, capable of producing with high precision certain parts of the calibres of the movements. The requirement was that the parts be identical and exactly suited to the firm’s existing calibres, and this he accomplished. A fully equipped factory, the first of its kind, was soon to follow. So, quality was actually enhanced, while production increased. In 2004, this commitment to technology in conjunction with human expertise is there to see at the facility in the Vallée de Joux.

What does Hubert actually do? The welcome mats are sticky, to remove any dust from the soles of your shoes as you enter each room in the watch making complex. Many windows, strict climate control, artisans bent keenly over their particular piece of the puzzle that ultimately becomes a watch on someone’s wrist as they stroll down Bay Street or Howe, or Fleet, or Madison or Faubourg. Many of these artisans wear headbands supporting a magnifying eyepiece, since many of the hundreds of components are too tiny to see accurately with the naked eye. Certainly not accurately enough to, for example, see the slot in the screw head and the aperture into which said screw must be inserted and fastened. Some screws are in fact microscopic; 50,000 of them can easily fit into a simple sewing thimble.

Egerie l.

And here the genius of Leschot lives on. Finely calibrated machines manufacture these tiny screws, and several other parts, which are then assembled. Intricate relay systems and small, specific task-oriented conveyor belts adorn the various workbenches. Streamlining is too strong a word, but the assembly is certainly more time-effective than if all parts were manufactured by hand, and assembled without any mechanical assistance.

In this facility, Hubert is an enthused guide. “When you know the history, technology and artisanship have always been close together for our company.” The people at work here are quite young, and Hubert notes, a bit of a cloud passing quickly over his face, that “an entire generation of watchmakers, in the 70s and 80s, is missing. For a time we had no new watchmakers.” But now, the pool of talent is healthy again. And “polyvalent”, Hubert notes. They do different tasks, partially to avoid monotony, but more importantly to learn every aspect of the craft.

There is an elaborate system of checks and controls as well. Before the watch in assembly moves from one phase to another, it is rigorously checked, to ensure all is perfect. Anything amiss would affect the subsequent steps, so the technicians are very careful, and the machines used to measure accuracy are highly calibrated. For example, the hairspring measurements, which must be exact, and the escapement wheel, are together put under a microscope. “At this stage, you can tell if it is perfect, or not so perfect” Hubert says. “And we only sell perfect watches.”

Egerie 4.

Vacheron-Constantin produces approximately 16,000 watches each year. Of these 4,000 or so watches are made with varying degrees of complications. These complications are what the company built its reputation on, and continues the tradition every year. Extremely complex chronographs can have ten or more complications.

In the age of digital, of quartz technology, accuracy is no longer a question. Claude-Daniel Proellochs is Vacheron Constantin’s CEO; “Design is my passionate hobby. That’s why I am involved with the team. Ideas can come from anywhere, so long as you are open to it. We made a design for a “jumping hour” watch in a bar in Berlin one evening. It has been a great success.” This explains Vacheron’s existence, in a way; “quartz can deliver a more accurate reading of time than the best human-made watch. So why do we do what we do? It is about history, about beauty, about design. But then, how crazy is the fight for perfection, for beauty? And then have people feel it, and then of course to wish to pay for this. People don’t really need a hand-made watch. For our company, it is much more than keeping time, though of course our watches keep time perfectly.”

Proellochs came to Vacheron in 1988, and has presided over the Richemont Group’s purchase of the company, and over a steady rise in recognizability and prestige for the brand. “We needed to create better awareness, to market the brand better. And when I came in, the average age of employees was 54. Now it is 37. This, I think, is very healthy.” He is relaxed in his office, no immediate travel plans, having returned from Paris where he visited Jean-Louis Dumas, his counterpart at Hermès. “For Hermès it is a little different. For me, I spend a lot of time in boutiques, wherever I go around the world. Because after-sales is the most important thing. The curve of satisfaction must go up, for each client, and then you have won.” The company understands its markets well. “We want to meet cultures, not to bring ours in. Respect for others is the first key. When you have collection, you have a spine, a universal. But each culture has its particular tastes as well. Diamonds in the Middle East, yellow gold in China, better straps in Italy, white gold in Japan.”

It is not an overtly easy sell, although many specialized lines are pre-sold, sometimes years in advance. For Proellochs, as for Hubert Hirner, the painstaking attention to detail is the point. “I tried to finish a watch myself once, and I could not do it” he says, in something bordering between deep respect and awe for the craftsmanship at work every day in the Vacheron facilities.

About the watch. 50,000 microscopic screws, okay. Sticky mats, dust free environments, repeated quality checks, microscope eyepieces, okay. Edward Ruthurfurd’s novel London ex-plores that city’s history from the time of Julius Caesar onwards; mercantile shipping and the need for accurate chronometres and horological devices is an important part of that story. Even in Herman Melville you can find philosophical musings about horologies and chronometers. If only Ahab had been a touch more scientific, perhaps, and less tautological. The first, very large, marine chronometres made navigation much safer, and technological advances in this area made for commercial success due to serious advantages in navigating the seas. The practical applications of precision, and then of size, were a major factor in the Industrial Revolution.

And so, about the watch. Wound by a key, and worn in the pocket. The winding crown came into being late in the 19th century, and although select women’s watches were worn on the wrist as early as 1870, they were not commonplace until the 1930s. But, about the watch. It is a barrel and a mainspring, which work together to accumulate mechanical energy to power a watch movement. The barrel’s circumference is toothed. The mainspring has an extremity hooked to the barrel, the other end in a reversed curve, pressing against the barrel’s inside wall. As the mainspring unwinds, it impels via the barrel the teeth, which engage a set of gears that convey power to the escapement. The escapement is aptly named: it is designed to allow miniscule amounts of mechanical energy from the mainspring to literally escape, at a regular rate. The escapement is composed of: the escape wheel, a lever with fork, and a roller fitted with an impulse pin.

The escapement sustains and calibrates the oscillations of the balance wheel and spring, which in turn determines the rate of movement. Standard watch-movement vibration rates range from 18,000 vibrations per hour to an upward level of 36,000. The balance wheel, impelled by the impulses from the escapement, oscillates at a set frequency around its dead point, or position of rest. So, these mechanical parts, put together by hand, require great finesse, particularly in adjusting the rate of the movement. As Hubert Hirner puts it, “the job is to neutralize the inevitable residual rate variations.” This is the “timing” of a movement.

Master Toledo.

So, we have the basics, the simple stuff. Traditional watch making in the grand style meant the introduction of various “complications”. In the 19th century, Breguet invented the tourbillon, in effect a cage that enabled the movement inside to rotate and eliminate gravity’s effect on the increasingly small and slender timepieces of the day. It was one of the first of over a dozen complications that can be introduced into a handmade watch. Rubies, now man-made, but of a quality that, for watch making purposes exceeds that of the natural stone, are an important part of the machine, providing just the right amount of resistance in the movement; a highly complex chronograph may use 35 gems.

A chronograph is a watch by another name; it is, however, a distinct denotation of quality. To observe such a device under a microscope, to see the mechanics of it amplified, is to instantly understand the overused word “intricacy”. The wheels near the hairspring move in response to five vibrations per second. The distinctive Maltese Cross, utilized in Vacheron’s cage as a winding-tension brake, and as a formal signifier of excellence since 1880, looms large under the microscope. Hubert comments lightly “watchmakers require instinct, feel, and a massive amount of technique.”

One of his colleagues has just put the last touches on a highly complex minute repeater, a watch he took nearly 18 months to assemble. Above his workbench is a graph of the lunar phases: he begins making the watch according to the moon, and calibrates the finish by that pale marker as well. “We are known above all for the complications in the movement,” Hubert asserts. He shows this newly finished watch under the microscope. It is a special piece; not only is it a minute repeater, which means it can, thanks to a delicate hammer, gong and wheel, chime the hour, quarter hour and minute. The age and quarter of the moon are displayed on an inset face; another inset face is a perpetual calendar. The 107 parts, attached to 41 bars and bridges, operated by 76 wheels and pinions secured by 305 screws makes it a paragon of design and execution. But that’s not all. This watch is also a skeleton: you can see virtually every moving part, every one of its unprecedented 46 gems, even as it is strapped lithely to your wrist. It will keep accurate time for over a century.

It is an astounding piece of work. Hubert notes that every watchmaker somehow imparts a distinctive touch to the work, so he can vouch that this particular piece was done by his immediate working neighbour, and not by anyone else in the company. This piece of artisanry costs $450,000 USD, but cannot be purchased; it was a special order, one of very few the company does.

Greenwich time was adopted across the world in 1884, following Canadian engineer Sir Sandford Fleming’s system of Universal Time and time zones, which he introduced to the world in 1779. Prior to that, each community, north, south, east, west, kept its own time, in keeping with the ancient device called a gnomon. You might know it as a sundial of sorts. But the need to make time itself conform to the exigencies of commerce proved too intense for the old methods to hold their dominion. So just as the consensus was reached that the earth indeed rotated around the sun and not vice versa, watchmakers were beginning the attempt to put the timekeeping equivalent of angels on pinheads. What you have in a watch made at Vacheron Constantin is an embodiment of that impetus, towards understanding the order of the universe, assuming such a thing exists at all.