Savoy hotel next to his Savoy Theatre in London in 1889, he set an audacious new bar for luxury accommodation. The Savoy was the first hotel to generate its own electricity (it used steam generators), and its en suite baths were another unprecedented indulgence. The Savoy also featured “ascending rooms” (the word elevator was not yet commonly used). Even though they were slow, the lifts made it possible to build suites with sweeping views of the river Thames, as depicted in paintings by Claude Monet, who stayed there. The Savoy’s glamour and extravagance were epic, attracting American and European stars of stage and screen, as well as other cultural luminaries for generations.

The Savoy’s crème de la crème ethos even applied to its beds, which were commissioned in 1905 from the esteemed London upholsterer James Edwards Ltd. In 1924, the Savoy Group acquired James Edwards Ltd. to ensure its premium beds remained exclusive to its portfolio of hotels, which had grown to include the Berkeley, the Connaught, and Claridge’s. Prominent guests frequently purchased the beds for their own homes. In 1980, King Hassan II of Morocco ordered 24 beds for his palace after sleeping on one at Claridge’s, telling the hotel manager it was “like sleeping on a cloud.”

Today, the classic Savoy bed goes by the name No. 2. It is still produced by hand in London by Savoir Beds, which was established after investors acquired the Savoy Bedworks (which had changed its name from James Edwards Ltd.) in 1997, beating out the highest bidder by committing to maintaining the same quality and craftsmanship with its few remaining employees. In 2005, Savoir acquired a quality bed manufacturer in Wales to produce its No. 3 and No. 4 beds. (The No. 1, in case you were wondering, was created in 2010.)

In 1980, King Hassan II of Morocco ordered 24 beds for his palace after sleeping on one at Claridge’s, telling the hotel manager it was “like sleeping on a cloud.”

Now managed by Fairmont Hotels & Resorts, the Savoy—which completed a £220-million ($355-million Canadian) top-to-bottom refurbishment in 2010—furnishes its top suites with Savoir beds, as do a handful of hotels around the world including the Peninsula New York, Ashford Castle in Ireland, and Fairmont Baku, Flame Towers in Azerbaijan. But the bulk of Savoir’s business is with private clients and interior designers, who can choose from different mattress configurations and levels of firmness (even within the same mattress) and dozens of bed designs, some of which are the creations of prominent designers who have partnered with the brand.

This year, Savoir released a new bed by Madeline Weinrib, an American interior and fabric designer, who covered Savoir’s Holly headboard in her blue Bara Ikat fabric. Sacha Walckhoff, product designer and creative director for Christian Lacroix, designed the B 01 bed, taking inspiration from Savoir’s mattress pocket springs, which are produced in-house; the bed’s design features pod-style cubbyholes and a customizable headboard made of pocket springs.

For those who demand nothing less than bespoke, Savoir specializes in custom commissions, no matter how daunting. “There’s a price, but we never say no,” says managing director Alistair Hughes. “People like things that are made for them to their taste.” As Hughes notes, the company has produced rotating beds operated by iPad and other special orders with price tags that can reach up to a quarter of a million dollars.

The company has produced rotating beds operated by iPad and other special orders with price tags that can reach up to a quarter of a million dollars.

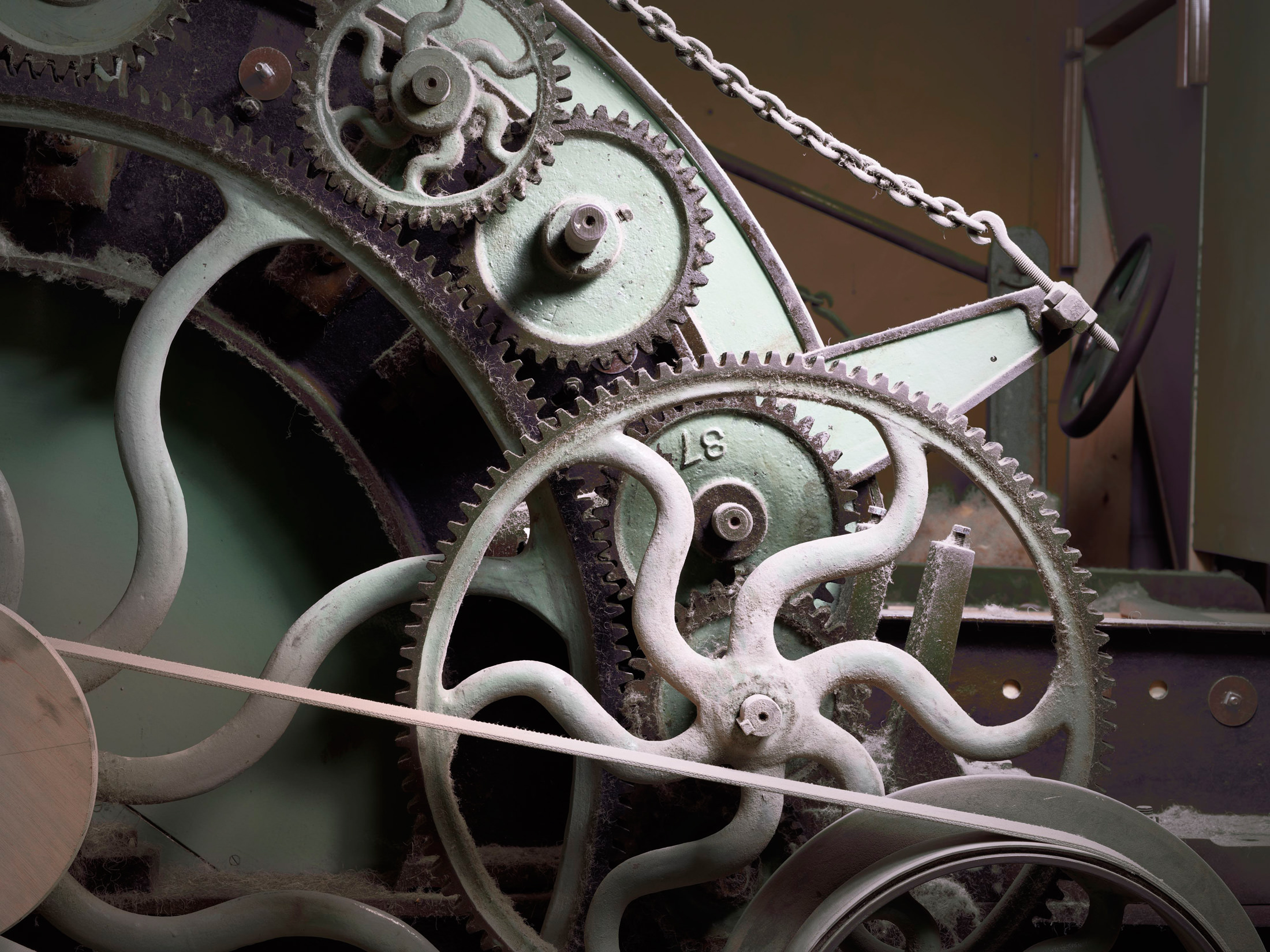

Savoir’s ability to realize its clients’ whims can be attributed to its manufacturing methods. Typically, high-end beds are made on a production line akin to what you’d find in a car factory, where each worker performs a task and the bed moves to the next station for the next task. At Savoir, however, each bed is bench made by one upholsterer from start to finish. Rather than an assembly line, Savoir’s workshops have oak trestles where skilled craftspeople wield hammers and needles.

The bench-made process results in the job being more interesting and gratifying for the artisans, who perform a variety of finely tuned tasks, such as hand tying the springs eight ways to ensure they stay in place, hand tufting with a needle to keep the natural materials inside from moving around, and hand sewing to close the Trellis ticking, which was designed more than a century ago by the wife of (aforementioned Savoy founder) D’Oyly Carte. The entire process requires upwards of 80 hours, and the artisan completes the job by signing their name on the label.

Given the intensity of the labour required, Savoir produces only about 800 beds per year, with prices starting around $10,000 (U.S.) for what Hughes calls a “naked bed”, meaning a basic mattress and box spring. Typically, though, a client will order a complete bed with a headboard upholstered in special fabric or even animal hide or another exotic material. “We are effectively upholsterers—that’s our skill,” says Hughes.

Given the intensity of the labour required, Savoir produces only about 800 beds per year.

Inside the mattress, surrounding the chosen springs and placed for the desired firmness on each side, the artisans lay layers of cotton, English lambswool, Mongolian cashmere, and long, straight horsetail sourced from South America. The horsetail is sent to Switzerland for steam cleaning and is coiled into 50-kilogram bales of rope, which are then uncoiled and combed at Savoir for optimal loft. Savoir uses vast quantities of the hair in its mattresses and toppers, which should be refreshed after five to seven years. The mattresses can last for decades with proper maintenance.

“One thing about animal hair is that if you’re hot, it wicks moisture away from you, and if you’re cold, it insulates you,” explains Hughes, who adds that in addition to excellent temperature regulation, horsetail and other natural materials Savoir uses breathe and allow moisture to evaporate, while synthetic materials only trap it. “To lay hair is quite a skilled job and it takes time to learn how to do it, and then you have to know how to control it because it wants to move everywhere,” he adds. “Most manufacturers do not use it because it’s expensive and quite difficult to work with. But it gives the best result.”

In the end, superior performance is the reason for all the expensive materials and hand craftsmanship. “People like the idea of craft, but there’s only so much you will pay just because it’s craft,” says Hughes. “You actually want it to perform, so we make things the way we do because it gives a better result.”

While the word luxury is bandied about so often these days that it has almost lost its meaning, Savoir checks all the boxes when it comes to quality, craftsmanship, heritage, authenticity, and exclusivity. Bespoke service is another defining characteristic of a true luxury manufacturer, says Hughes, who draws comparisons with a number of legendary brands including, of course, the Savoy hotel.

_________

Never miss a story. Sign up for NUVO’s weekly newsletter.